PLASTIC STEEL LIQUID B 10210, 10230

Category:CASTING & MOLDING

Brand:

Plastic Steel Liquid B

P/N 10210 (454 gr.) .03 m @ .025 in (6.3 mm.) Thickness

P/N 10230 11.36 kg. (25 lbs.) .083 m @ .025 in (6.3 mm.) Thickness

MOLD, CASTING & LIQUID EPOXY COMPOUNDS STEEL AND ALUMINUM CASTING

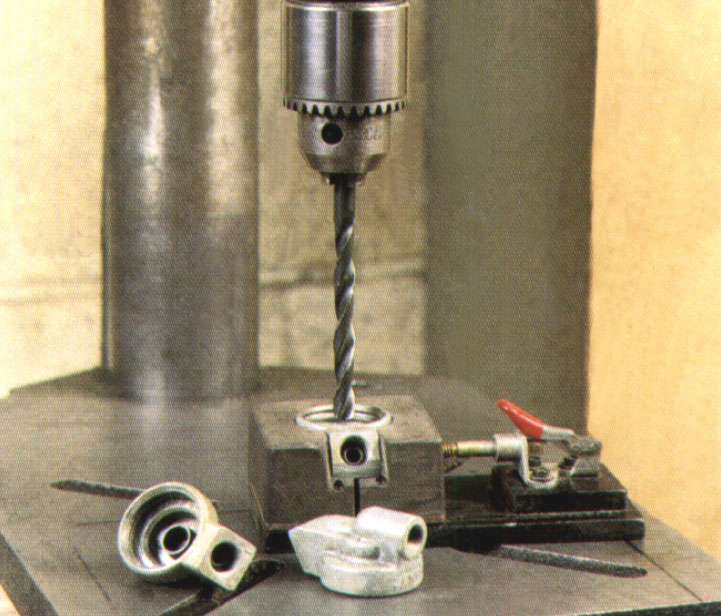

Use: Steel Filled Liquid Epoxy for making holding fixtures, forming dies & molded parts. Once hardened, material can be drilled, tapped and machined. Low Viscosity. Self-Leveling.

- Drying Color: Dark Grey Liquid. Brush a thin coat on the mold substrate, then pour.

- Working Time: 20 minutes.

- De-Molding Time: 12 hours.

- Full Cure: 16 hours.

- Mix Ratio by Weight: 9:1

- Working Temperature: Dry: 105 °C , Wet: 50 °C

- Tensile Strength: 2,800 PSI. (19.30 MPa)

- Compressive Strength: 10,200 PSI. (70.32 MPa)

- Hardness: 85 Shore D