R-FLEX BELT REPAIR 15565

R-FLEX Belt Repair: P/N 15565 1 lbs. (454 gr.) P/N 15565 4 lbs. (1.8 kg.)

Devcon R-Flex is formulated to quickly repair tears, gouges and holes in styrene – butadiene rubber (SBR) heavy weight conveyor belts. Offering excellent abrasion resistance as well as superior adhesion, the R-Flex urethane compound is easy to mix and cures quickly – the repaired belt can be back in service just 90 minutes after application. High adhesion to SBR Belts.

- Drying Color: Black Med. Hard Rubber.

- Working Time: 7 minutes.

- Functional Cure: 90 min

- Full Cure: 16 hours.

- Self-Leveling: Non-Sag

- Mix Ratio: Mix Completely for Best Results.

- Volume Mix Ratio: 88:12

- Working Temperature: Dry: 85 °C , Wet: 49 °C

- Adhesion 7 days: 128 PLI.

- Tear Resistance: 1,462 PLI.

- Abrasion Resistance: 270 mg. loss/1,000 rev.

- Hardness: 92A Shore A

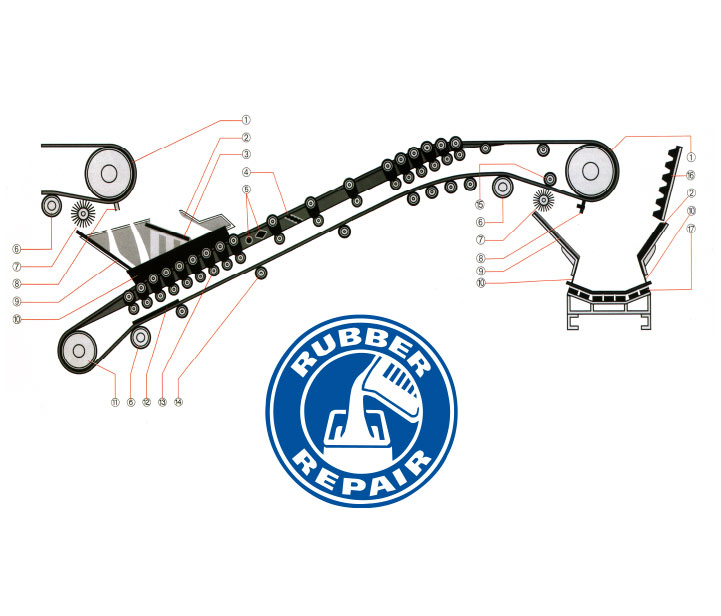

Urethane Molding and Rubber Repairing Conveyor Belt Repairs

Urethane Molding and Rubber Repairing Conveyor Belt Repairs

Two different types of belting repairs can be performed with Devcon’s Flexane technology. The most common repair is a

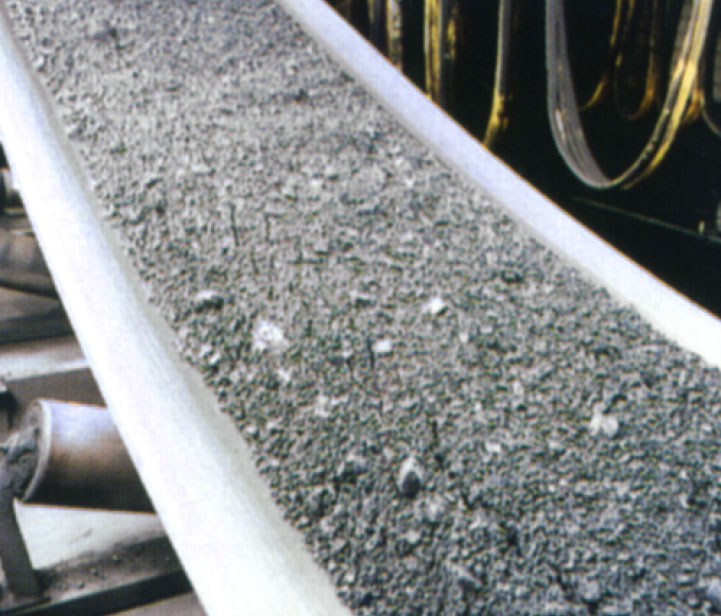

“Hole” in belt. This is caused when by when the aggregate being transported wedges itself into the wiper area, thus a tear or hole in the belt. The other type of repair occurs at the “Clips”. This area is where the belt is spliced. Some conveyer belts have metal detectors at the pully area, so you need to coat the clip area to hide the metal pins. The fine aggregate gets into the pins of the metal splice and wears out the “pins”. Therefore it is recommended that the metal splice area be coated with Flexane. We will show both repairs. They are as follows:

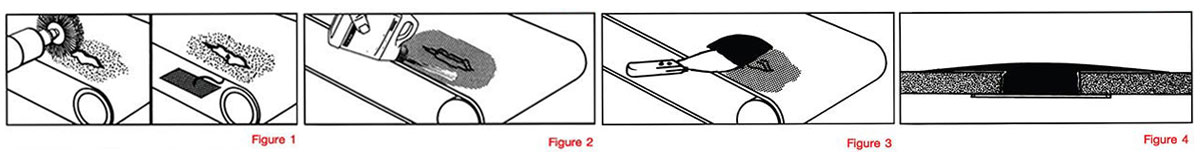

- Surface Preparation: Follow the section under “Clean Rubber Surfaces” Remember to grind the belt area well, to get

good adhesion. Figure 1 For a “Tear” or “Hole” in Belt: First apply duct tape underneath the belt to stop anything

from going through. Then abrade the area, cleaning off the dust when finished. Figure 1 - Apply FL-20 Primer around the tear and approximately 4-8 inches around the tear. Let dry for 30 minutes. Figure 2

- Mix Flexane 80 Putty and apply into the tear and around the tear area 4-8 inches. Figure 3

- By applying Flexane 80 Putty around the tear area and “feathering out” the Flexane material, you make a repair that

will be almost on the same plane as the belt, not a “bump” on top of the belt. Apply at least an 1/8” of material to the belt for strength and flexibility. Figure 4